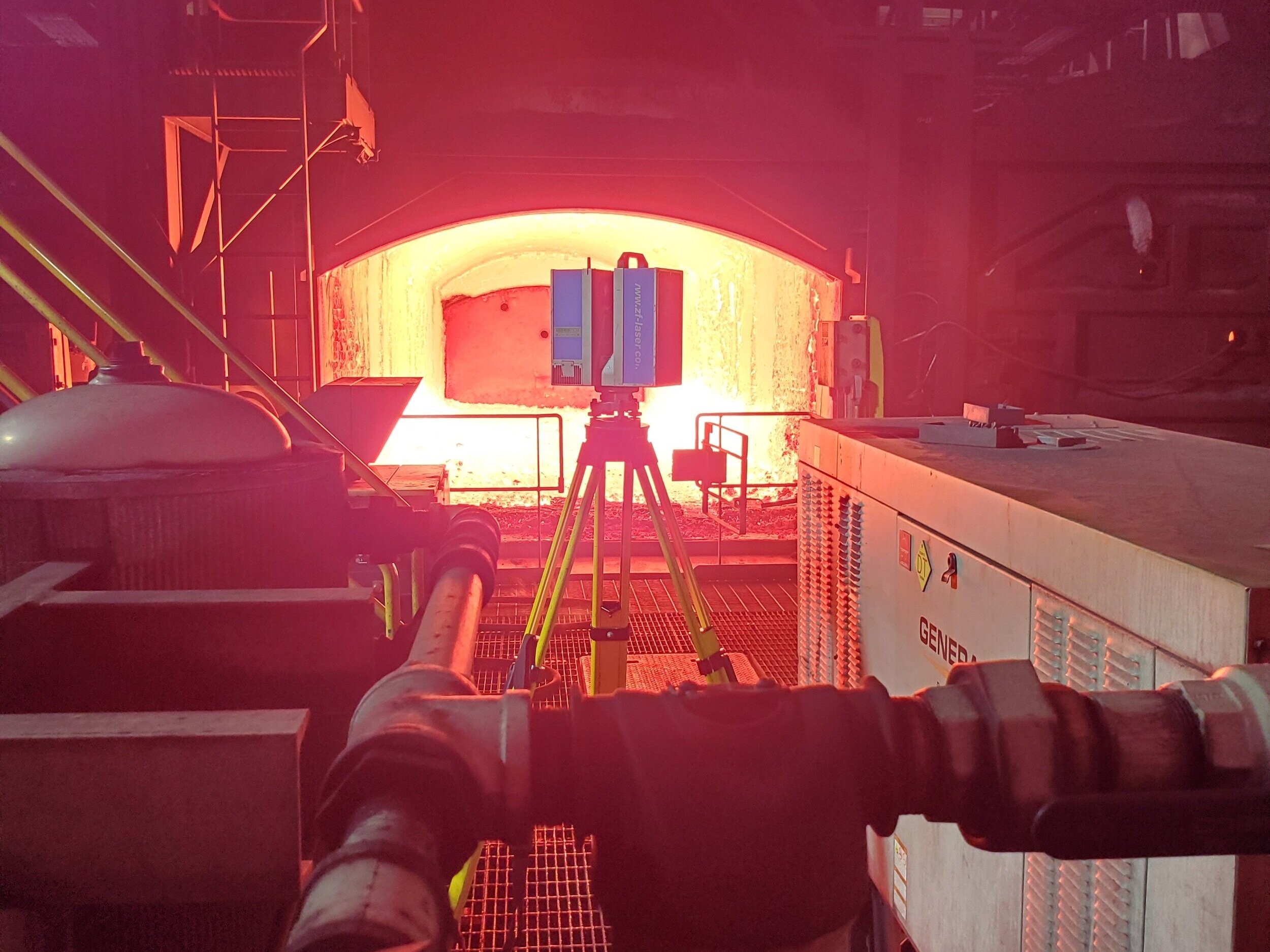

Coke Battery - Refractory Wear Study

Client: Global Raw Material Processing and Handling Company

Location: East Chicago, Indiana

Year Completed: 2020

Services Provided: Quantify Refractory Wear

Description/Highlights: Utilized the laser scanner to collect measurements inside of ovens that were in excess of 2,000°F. Previously refractory wear could only be assessed during shutdowns. With the laser scanner technology, we were able to map the condition of the refractory in the running condition. This allowed the team to manage and plan remediations months in advance.

Contact Falk PLI to discuss a similar project for your company!